What kind of wood works best for furniture? It is a more complex question than it appears at first glance. However, you will probably be aware of it if you are in the process of furnishing your home.

Your budget and anticipated usage determine the answer. Aside from the type and grade of wood used in a furniture piece, the technique utilized to make the item is another issue. It significantly impacts the price level of the wood furniture you are contemplating.

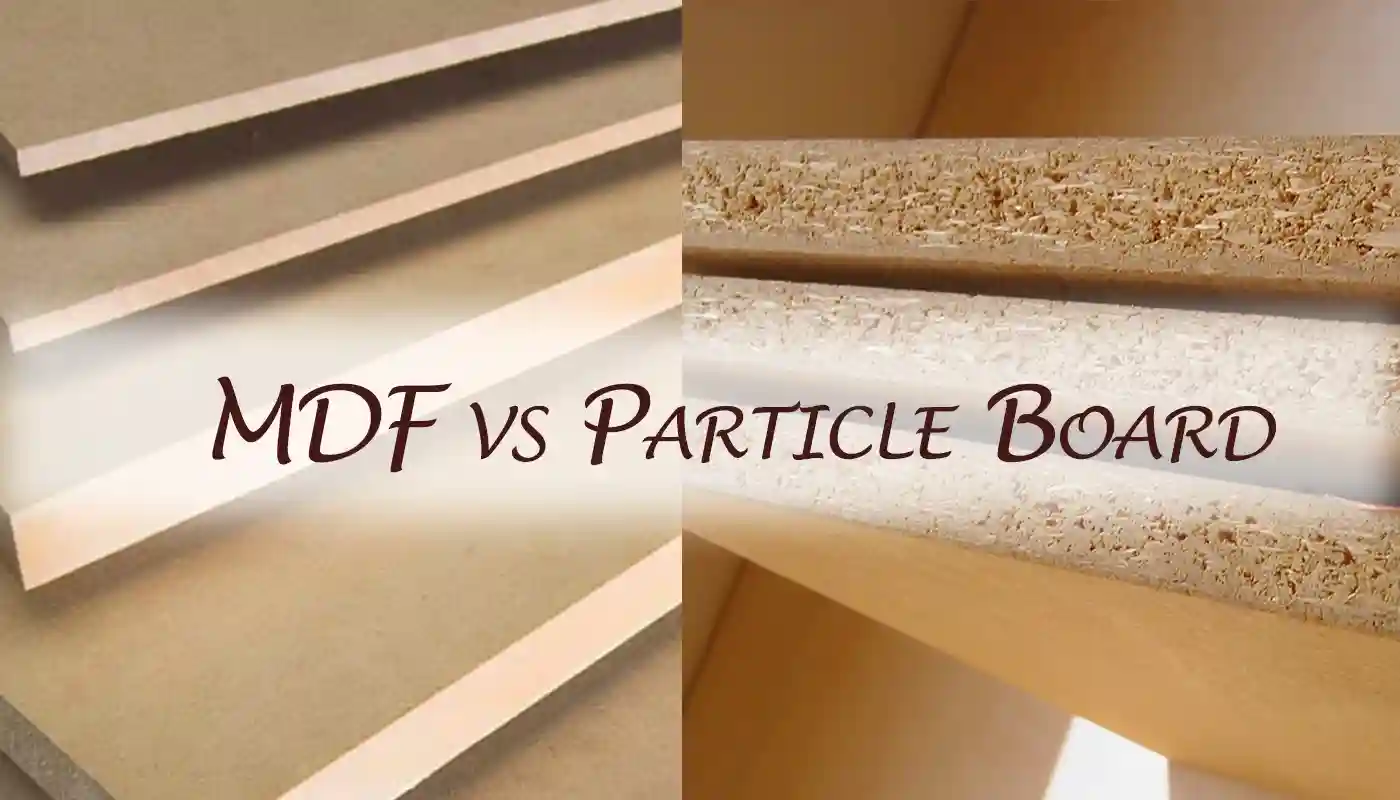

Solid wood is a popular material for home décor; however, it's expensive. Furniture producers seek innovative ways to reduce expenses by employing less costly materials. MDF and particleboard are two alternate materials used in home décor. Let's explore both in detail below.

MDF, or medium-density fiberboard, is an artificial material. It is made of wood fibers combined with wax, glue and high pressure before being pressed into flat panels. Whole MDF sheets are usually four by eight feet in dimension and are available in thicknesses ranging from 1/4 to 1 inch (actual size is 49 x 97 inches). In addition to being utilized to construct homes, it is also used to create furniture and cabinets.

MDF is nominally comprised of wood, but its structure is very different. If you try to bend an MDF board, it will snatch rather than warp. It is why engineered wood outperforms its competitor in terms of moisture resistance. Of course, if you submerge it in water, the board will eventually be damaged. The piece will expand and shrink when exposed to airborne moisture while maintaining its general integrity and shape.

B) MDF is inexpensiveMDF boards are generally less expensive than genuine wood. But, of course, there are a few exceptions when comparing high-end MDF to some of the less costly forms of timber. Another advantage of engineered wood is that it is easier to find than maple or white oak, especially if you require a specific size.

C) MDF is a good material for cabinetsThe benefits of engineered wood cabinet doors are undeniable. Thanks to manufacturing flexibility, interior designers can choose between flat-paneled, partially, entirely overlay, inset, euro-styled, and raised designs. In addition, certain types of MDF like HDF and HDHMR provide additional moisture resistance, which is critical for kitchen and bathroom furnishings.

MDF has a very poor screw holding capacity since its made from wood fibers which may move as the screw punches itself through them.

B) Vulnerable to heatRemember that wax and resin are used to make engineered wood. Because of this, MDF units should be kept away from heaters, radiators, fireplaces, ovens, stoves, or outside during a hot summer.

C) MDF cannot withstand an excessive weightMDF is used massively for units such as wardrobes, bookcases, kitchen cabinetry, etc. But putting too much weight on MDF boards makes them incapable of withstanding such loads. It may cause them to sag.

D) MDF costThe price of an MDF board depends on many factors, like:

There are four types of MDF

MDF combines wood fibers with resins and other ingredients. The more wood fiber this mixture contains before being pressed (to a certain level), the better the quality of the MDF. As a result, MDF sheets with a higher percentage of wood fiber are strong and more durable but also more expensive.

The larger and thicker the MDF sheet is, the higher the price.

The next cost-determining aspect is the brand of MDF you purchase. Kronospan, Medite, Spanolux, and Finsa are some of the most well-known and pricey MDF manufacturers. Yet, numerous alternative brands and generic MDF companies may charge far less for their products.

Hence, on average, a 4*8 foot sheet of MDF costs between $15-$60, while a 2*4 foot finished sheet costs $60-$150.

What is Particle Board?Particle board has recently acquired appeal in the building industry due to their versatility and low price. It is widely used to manufacture various types of furniture, paneling, and partition structures. Particle board is a wood-based engineered product from waste materials such as wood chips, sawdust, and shavings. It is sometimes called a chipboard or low-density fiberboard (LDF).

Particle board type is one of the most crucial aspects. The single-layer particle board is the most fundamental and cost-effective variety. Finally, we have a slightly thicker and more waterproof three-layer particle board. Graded-density particle board, melamine particle board, cement-bonded particle board, veneered particle board, and laminated particle board are a few other, more specialized forms of particle board to consider. Particle boards with veneer and laminate are two of the most expensive varieties.

The next aspect that determines the cost of particle board is how well produced it is in the first place. High-quality particle boards will be manufactured in huge plants using high- quality hardwood chips and shavings, as well as high-quality resins and adhesives. Not all particle boards are created equal, so be sure you get one produced with high-quality materials. It is also related to the type of particle board in question, as laminated particle board is significantly higher in quality than single-layer particle board and hence costs more.

Another thing that may influence particle board pricing is its appearance. For example, low- quality particle boards with a rough finish will be substantially less expensive than high- quality ones with a smooth and attractive finish, such as laminated ones. The average price of a 4*8 sheet costs $10.

As you can see, MDF and particle goods are more affordable and trustworthy than solid wood or plywood. So, choose according to your choice and requirements and make your home beautiful.